Spiral mixers with bottom discharge DIOSNA SP 160 E and SP 240 E

Spiral mixers with bottom discharge DIOSNA SP 160 E and SP 240 E

For kneading different types of bread and pastry dough from wheat and mixed leavened dough, fine pastry, pizza, baguette.

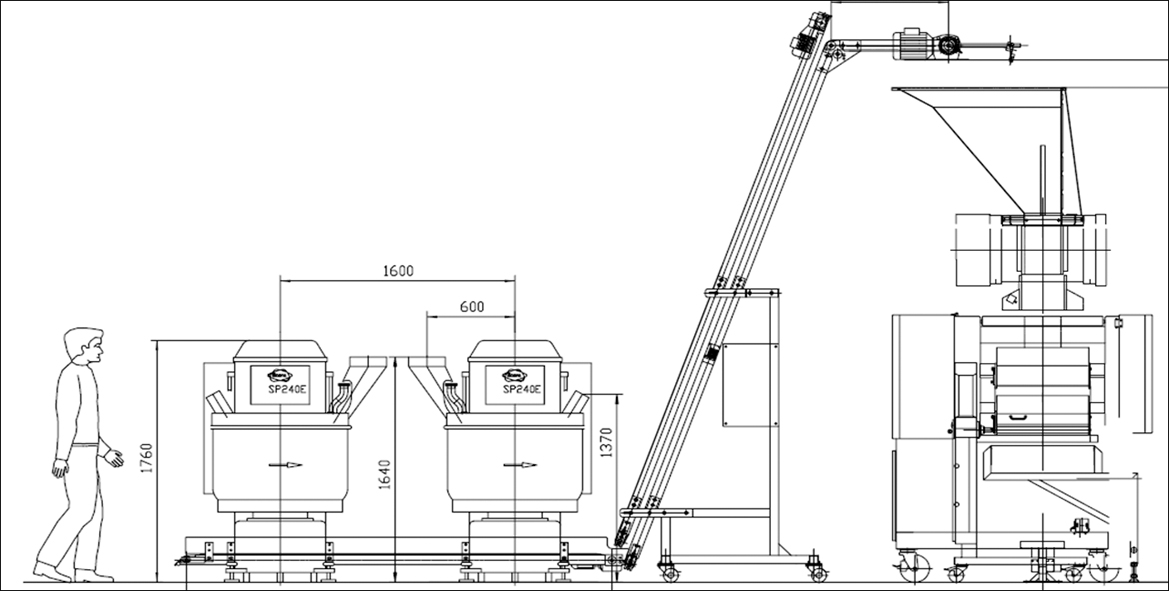

This most compact system design enables automatic kneading and dough conveying in one line.

The basic equipment includes one or more mixers with bottom discharge system. The raw material dosing into the kneading bowl is automatically. After the kneading time, the finished dough is discharged through the mechanical opening of the bottom discharge system. A belt conveyor or transport system for the bowls together with an elevator and tipper delivers the dough to the line portioner.

An extension of the system with automatic dough resting system via freely programmable resting and fermentation times is an optional supplement to this solution.

Advantages:

- Automated dough preparation from feeding through intensive kneading to emptying

- Suitable for all plant sizes from 160 kg to 600 kg dough per batch

- Significant work relief for uniform doughs

- Optimal kneading process by choosing the optimum kneading system

- Quick recipe change

- Dry, machine-friendly doughs – ideal for further processing

- Programmable timing, manual intervention possible at any time

Options:

- After the complete emptying of the kneading bowl the dough can either be transported quickly and directly in stainless steel containers or via conveyor belts

- With Spiralmixer or Wendelmixer

- 1-4 kneaders per kneading system possible

Spiral mixers with bottom discharge SP240E

Technical data:

| MODEL | SP 160 E | SP 240 E |

| Dough capacity (max) | 160 kg | 240 kg |

| Flour capacity (max) | 100 kg | 150 kg |

| Bowl volume | 260 L | 350 L |

| Tool power | 11,0/18,5 kW | 10,0 /16,0 kW |

| Bowl power | 1,1 kW | 2,2 kW |

| Weight (without transporters) | 1.700 kg | 1.510 kg |

| Dimensions

width height depth |

1.120 mm 1.940 mm 2.054 mm |

1.005 mm 1.760 mm 1.625 mm |